Boiler Repair and Maintenance: Advice from an HVAC Technician

As an HVAC technician, I frequently encounter boilers in need of repair and maintenance. A well-maintained boiler also runs more efficiently but also lasts longer. Let’s look at a guide on boiler repair and maintenance, covering common issues, simple troubleshooting, and when to reach out to a certified expert.

Boiler Repair Specialist

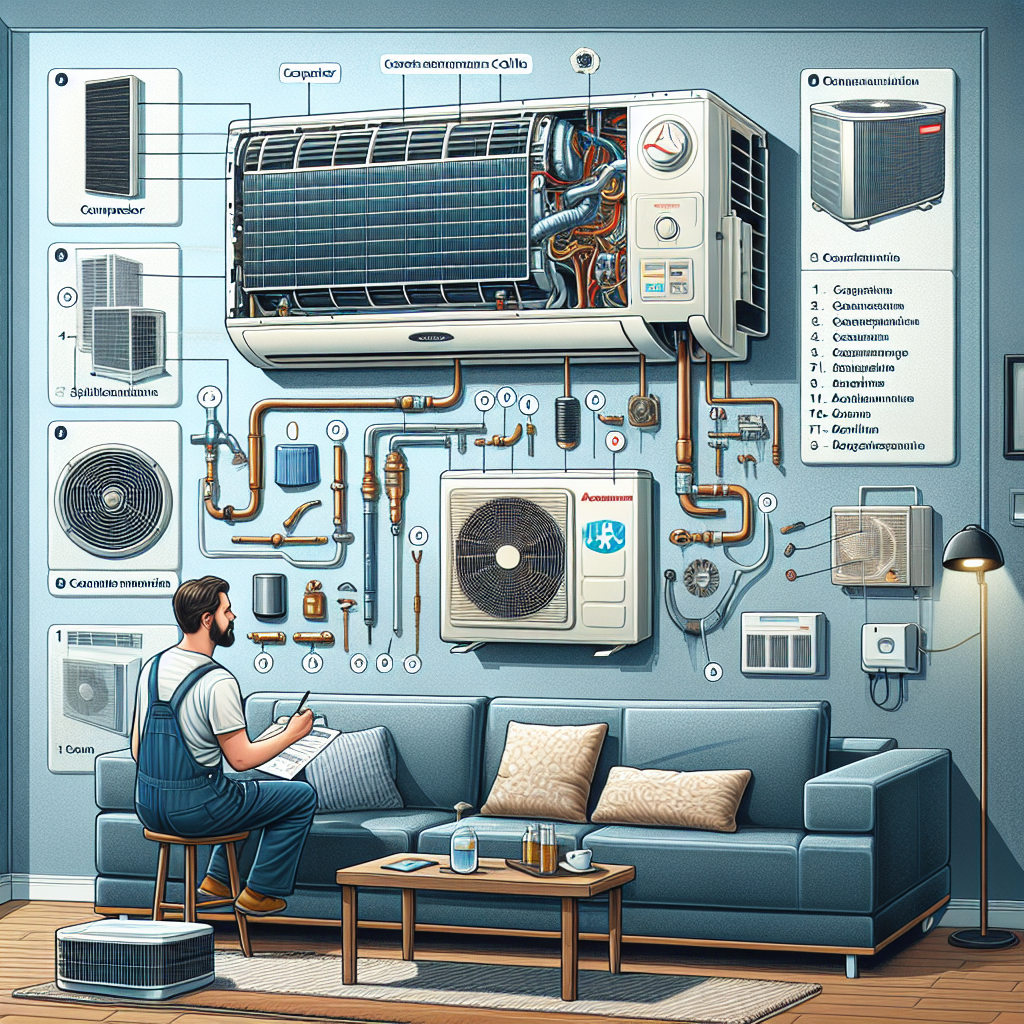

Typical Boiler Issues

Boilers can run into various issues over extended use. Here are some of the common problems I see in my work as an HVAC technician:

- No Heat or Hot Water: When your boiler doesn’t provide heat, it may be due to a problem with the thermostat, low water pressure, or a damaged valve or diaphragm.

- Strange Noises: Rattling or popping sounds from the boiler mean trapped air, a build-up of sludge, or even a worn part.

- Falling Pressure: A decline in system pressure can affect your boiler from operating optimally. Low pressure can happen to a failing part.

- Pilot Light Extinguishes: Older boilers equipped with pilot lights may encounter issues like flame loss due to drafts, a worn thermocouple, or a dirty fuel inlet.

- Temperature Settings Issues: Sometimes, the thermostat isn’t working correctly, which hinders temperature control.

Basic Boiler Maintenance Tips

Regular maintenance is crucial to ensuring boiler performance at its best. Here are a few simple maintenance tips that can prevent common issues:

- Check Boiler Pressure: Your boiler needs to run around 1 to 1.5 bars of pressure. If the pressure goes down, use the filling loop to bring it back up to the recommended range. Make sure not to go above the suggested range to prevent stress on the unit.

- Release Air from Radiators: Air pockets in the radiators lower system effectiveness. Use a radiator key to bleed out the trapped air, and check the pressure afterward.

- Keep the Boiler Area Clear: Obstructions might cause inefficiencies, particularly if it’s near materials. Maintaining a clear space improves performance.

- Clean the Boiler’s Components: Sediment and sludge can accumulate over time, impeding function. You may choose to flush the boiler to wash out sludge, which improves efficiency.

- Schedule Annual Professional Maintenance: A yearly inspection by a licensed HVAC technician is vital for catching small issues before they lead to breakdowns. A trained technician will assess the overall system, fix any wear and tear, and make sure everything is running smoothly.

Boiler Repair Specialist in Whitehall Pennsylvania 18052

When to Call a Professional

While some simple fixes can be done by homeowners, specific boiler issues should be handled a certified technician. Consider these cases where calling an HVAC professional is necessary:

- Moisture Around the Boiler: A boiler dripping water indicates a serious issue. Leaks can result in electrical hazards, so it’s essential to get a professional immediately.

- Ignition Fails: If the pilot light fails repeatedly, you could be dealing with an issue with the thermocouple, gas valve, or ignition system. Only an HVAC technician should diagnose these mechanisms to fix the issue.

- Persistent Noises: Frequent banging, whistling, or gurgling may mean a clogged pipe. A professional inspection is recommended.

- System Won’t Maintain Pressure: If your boiler is cannot hold pressure, a valve might be malfunctioning that requires a trained eye.

Final Thoughts

Keeping your boiler well-maintained is essential for a long-lasting heating system. Routine servicing and following maintenance tips help prevent unnecessary repairs. For more complex concerns, get in touch with a licensed HVAC technician—we’re here in keeping your heating runs smoothly all winter long.

Need Boiler Repair Specialist in Whitehall 18052? Trust Lehigh Valley HVAC Pros!